Plastic overmolding is an innovative manufacturing process that involves molding a plastic material onto another substrate or component. This technique allows for the creation of complex and durable products by combining different materials with unique properties.

Click to find more about what is plastic overmolding.

The Process of Plastic Overmolding

In the plastic overmolding process, a base material, often made of metal or plastic, is first molded to create the primary structure. Then, a second material, typically thermoplastic elastomers (TPE) or liquid silicone rubber (LSR), is injected onto or around the primary structure to form additional layers.

This dual-material approach offers numerous advantages. It enhances product durability by providing protection against impact and vibration while also improving grip and ergonomics. Additionally, it enables manufacturers to incorporate multiple colors and textures into their designs.

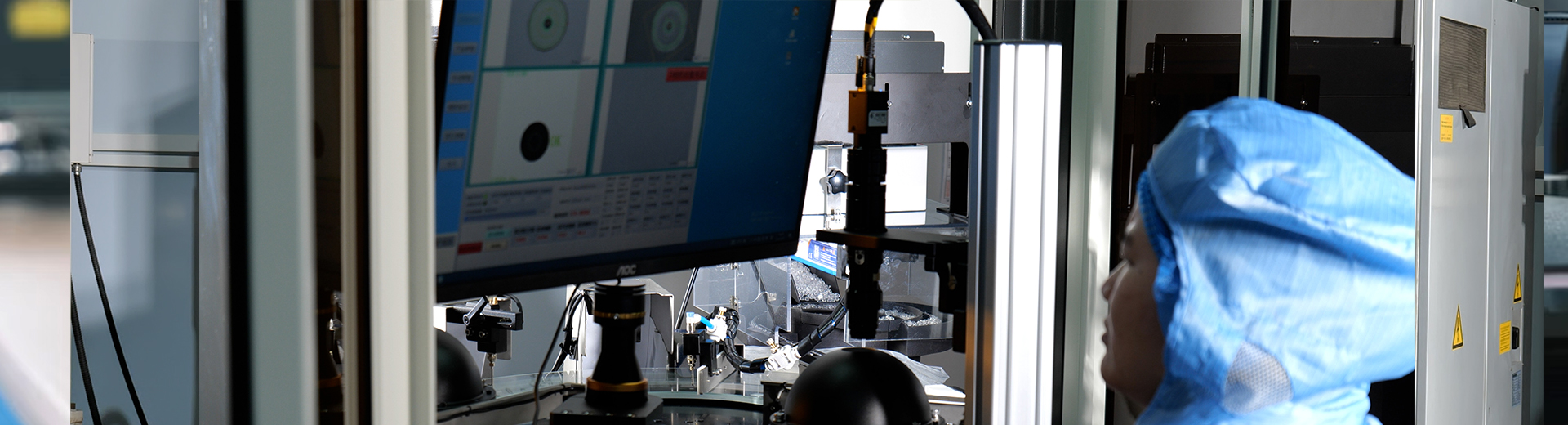

JVTECH: A Leader in Plastic Overmolding

When it comes to plastic overmolding expertise, JVTECH stands out as a leading provider in the industry. With years of experience and cutting-edge technology, they offer comprehensive solutions for various industries such as automotive, electronics, medical devices, and consumer goods.

JVTECH’s state-of-the-art facilities are equipped with advanced injection molding machines capable of precise control over temperature and pressure during the overmolding process. Their team of skilled engineers ensures high-quality production through rigorous testing and quality assurance measures.

The Advantages of LSR Molders

One popular choice for plastic overmolding is liquid silicone rubber (LSR). lsr molders provide exceptional flexibility in design possibilities due to its excellent flowability characteristics during injection molding. This makes it ideal for creating intricate shapes and thin-walled parts without compromising on strength or durability.

LSR molders also offer superior resistance to extreme temperatures, chemicals, and UV radiation. This makes them suitable for applications that require high-performance materials with excellent longevity.

In Conclusion

Plastic overmolding is a cutting-edge technology that allows for the creation of durable and versatile products by combining different materials. Companies like JVTECH excel in providing comprehensive solutions for plastic overmolding needs, while LSR molders offer exceptional design flexibility and durability. With these advancements, manufacturers can create innovative products that meet both functional requirements and aesthetic appeal.