Understanding Prototype CNC Machining

Prototype CNC machining is a fundamental process in the world of manufacturing that utilizes computer numerical control to create precise and complex parts from a wide range of materials. This technology empowers engineers and designers to transform their concepts into tangible prototypes quickly and with high accuracy, thus reducing the time-to-market for new products. Companies can create intricate shapes and designs that would be nearly impossible to achieve by hand. As industries evolve and the demand for rapid production grows, understanding the benefits of prototype cnc machining becomes essential for businesses aiming to stay competitive.

Benefits of Prototype CNC Machining

The main advantage of prototype CNC machining lies in its efficiency and precision. The automated nature of CNC machines minimizes human error, ensures consistency, and can operate for extended periods without interruption. This not only saves time but also reduces production costs significantly. For example, a company responsible for creating medical devices can rely on CNC machining to produce prototypes that adhere to strict safety standards while allowing for rapid iterations based on testing results. As businesses increasingly seek innovative solutions, the role of prototype CNC machining is becoming more critical.

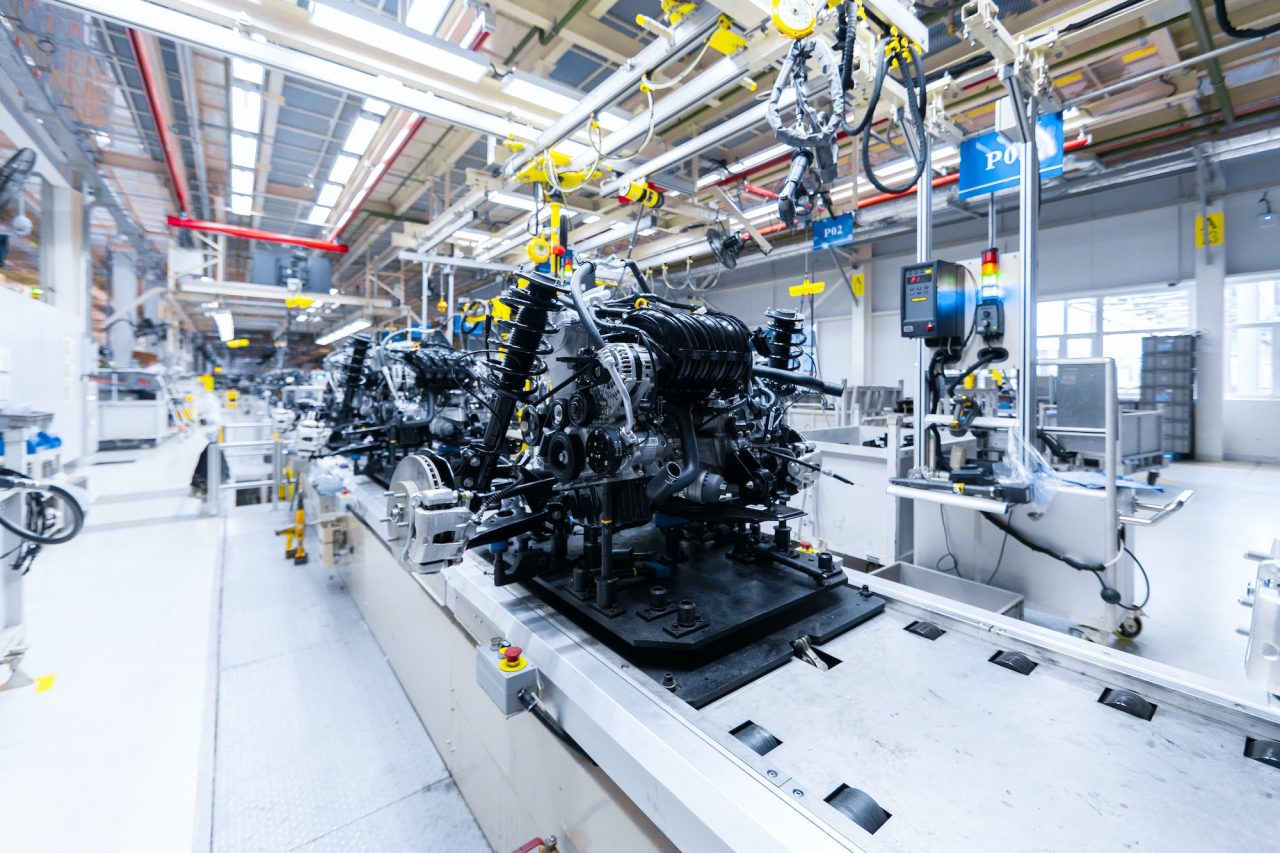

Real-World Applications

Prototype CNC machining has found its applications across various sectors, including aerospace, automotive, and consumer electronics. In the automotive industry, for example, engineers can use CNC machines to produce components for new vehicle models, allowing for thorough testing and refinement before mass production. This iterative process ensures that any design flaws are addressed early, preventing costly mistakes later on. Moreover, the technology is suitable for both small-batch productions and large-scale manufacturing, offering flexibility and scalability for growing businesses. By understanding the practical applications of prototype cnc machining, companies can harness its full potential in their operations.

CNC Online Service: A Modern Solution

In today’s fast-paced environment, many companies are turning to cnc online service for their prototyping needs. These services provide on-demand machining capabilities that allow businesses to send in their designs and have physical prototypes created quickly and efficiently. This eliminates the need for in-house CNC machinery, reducing overhead costs and freeing up resources for other essential tasks. For instance, a startup developing a new gadget can benefit from outsourcing their prototype work, allowing them to focus on marketing and business development instead of handling manufacturing logistics.

How CNC Online Services Enhance Productivity

Utilizing a cnc online service transforms traditional manufacturing methods, providing flexibility and speed that are vital for success. Customers can access advanced machining technologies without significant capital investment, as these online services often have state-of-the-art equipment operated by experienced professionals. This leads to higher-quality outputs and a faster turnaround time for prototype development. Additionally, clients can receive ongoing support and advice throughout the process, ensuring their projects align with industry standards and expectations. Ultimately, a cnc online service helps businesses adapt to the changing market demands while maintaining high-quality production levels.

Conclusion: Why Choose APT-Mold

In summary, prototype CNC machining is a crucial aspect of modern manufacturing, paving the way for innovation and efficiency across various industries. The emergence of CNC online services has further enhanced these benefits, making prototyping more accessible and cost-effective. For those looking for a reliable manufacturer with supply advantages, we recommend APT-Mold. Their commitment to quality and cutting-edge technology ensures that your prototypes will meet the highest standards, helping you achieve your production goals efficiently.